Erro de formato de e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

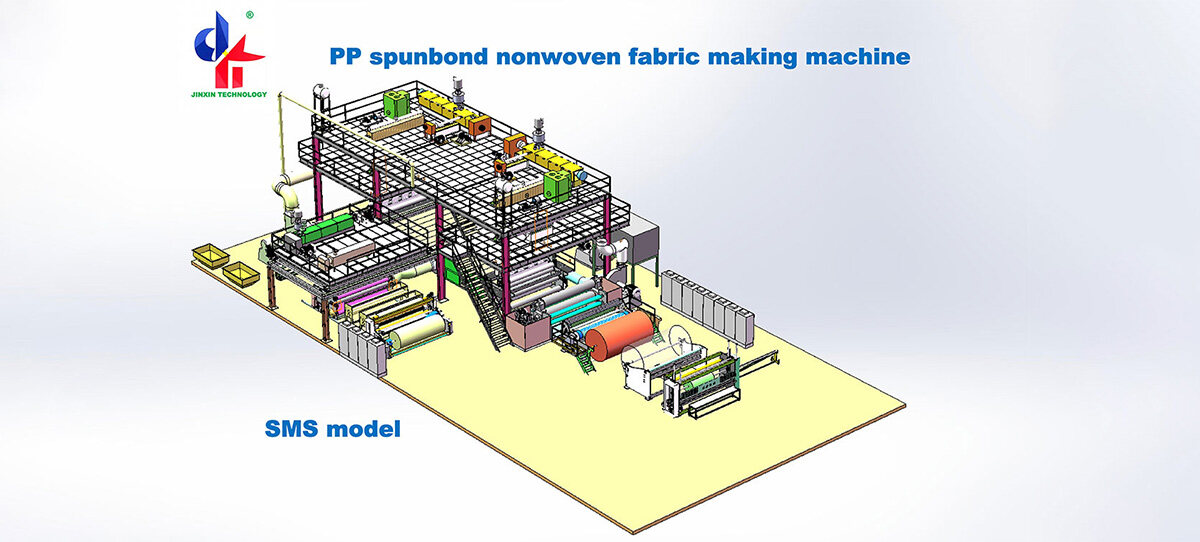

Máquina de fabricação de tecido não tecido spunbond SMS

The layout of the professional nonwoven fabric maker has been optimized and is now comparatively more compact. The professional nonwoven fabric production machine is frequently tiny in size because it can combine all the items that must be used in the nonwoven fabric processing into one piece of machinery to accomplish the same coordination.

| Model | JX-SMS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 40*16*12m | 40*18*12m | 40*22*12m |

| Mechanical Speed | 400m/min | 400m/min | 400m/min |

| Gram Weight | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

| Daily Output | 8-12T/Day | 12-16T/Days | 16-22T/ Day |

| Transformer Capacity | ≈800KVA | ≈1250KVA | ≈1600KVA |

| Power Consumption | 1200°-1650°Ton | 1200°-1650°Ton | 1200°-1650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Performance characteristics of the spunbond nonwoven fabric making machine

1.Professional nonwoven fabric making machine has been optimized in layout, which is relatively more compact. The nonwoven fabric making machine can integrate all the objects that need to be applied in the nonwoven fabric processing into one piece of equipment to achieve the same coordination, so the professional nonwoven fabric making machine is often small in size.

2.Stable operation is an important condition to ensure the output and quality of nonwoven fabrics. The nonwoven fabric making machine that can continuously maintain stable operation can make the quality of nonwoven fabric products uniform, achieve better product results, and play a very important role in nonwoven fabric manufacturing.

3.The nonwoven fabric making machine adopts the aluminum profile frame as the main body, the layout is solid and durable, it is not easy to rust, the application life is long, and the placement and protection are relatively convenient. Therefore, the experience of applying non-woven fabric equipment is relatively good.

4.The nonwoven fabric making machine can realize rapid and batch nonwoven fabric manufacturing by adopting the automatic control mode. Therefore, it can greatly accelerate the output of nonwoven fabric products, reduce labor costs, and bring higher benefits to the enterprise.

There are three different product lines in the application of spunbond nonwoven fabric machinery and equipment lines.

1.Nonwoven equipment manufacturing line type is used for air-laid mesh manufacturing lines of needled or hot-melt materials. It can be connected with the same pre-treatment branch line, has high-performance air carding equipment, and can be connected with a needle punching machine or hot-melt equipment.

2.The nonwoven equipment manufacturing line is mainly composed of high-speed carding machines, which can achieve a higher manufacturing rate of products.

3.The needling manufacturing line includes fiber pretreatment of opening and cleaning hybrid equipment, high-performance carding machine, cross common play machine, web drafting machine, needling machine, winding machine, and scanning unit at the end of the manufacturing line. This nonwoven equipment manufacturing line can be used for all household non-woven manufacturing applications.

SMS spinning melt composite nonwoven fabric manufacturing process and technology. The manufacturing line adopts ultra-high precision die spinneret processing means and deep manufacturing technology. The monofilament produced is thinner and more symmetrical, and the fabric texture is more gentle, which can greatly meet the needs of different customers.